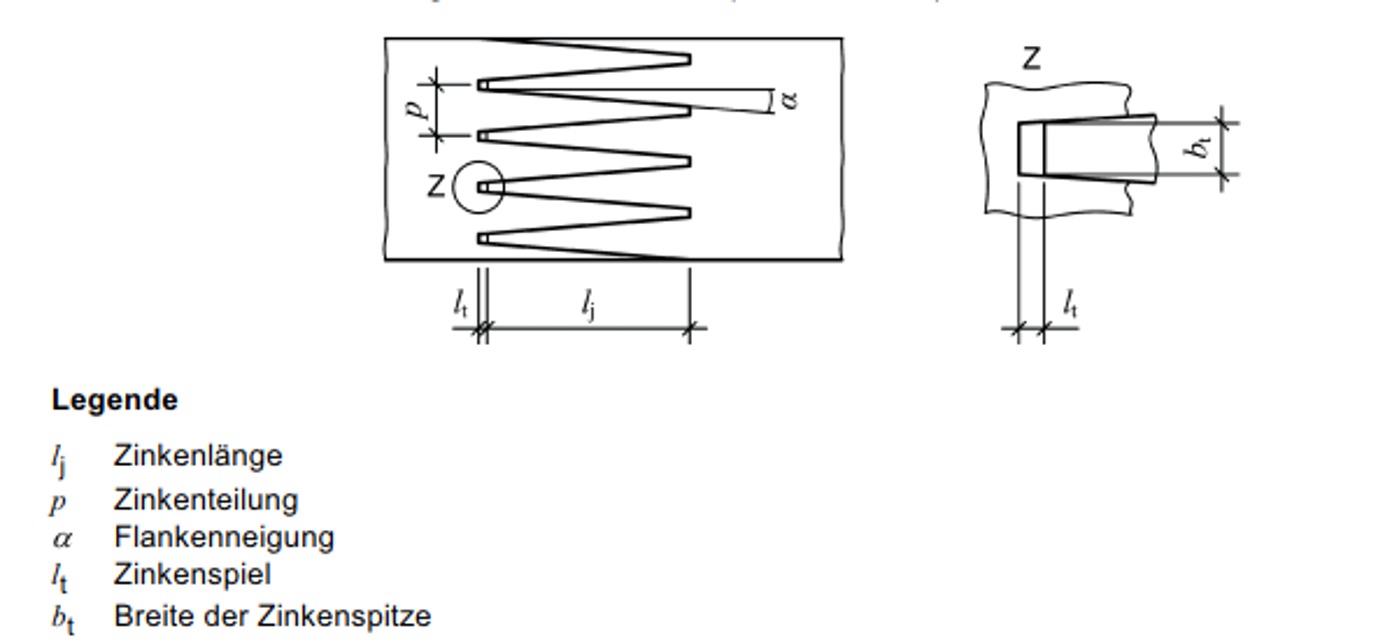

Finger-jointing

Finger-jointing is a tried and tested glue joint that is used in many glued timber constructions to create load-bearing longitudinal joints. It is often used in wood glue construction for solid softwood and glued laminated timber.

Finger joint lengths and load

for finger jointing

For single boards for glued laminated timber and smaller timber parts, the tine lengths are usually 20 mm. The glue joint in finger-jointing is mainly stressed for shearing. This means that the glue must primarily withstand loads that run parallel to the joint.

Production of

finger joints

Finger joints are produced in automatic finger jointing lines. In this process, the ends of two pieces of wood to be joined are provided with matching prongs (milled) and glued together under pressure. In this way, wooden components of any length, such as boards, can be made into lamellas in a short time by joining many individual parts together.

General finger joints and

universal finger joints

To a lesser extent, large overall cross-sections of glulam are also connected by so-called general finger-joints or universal finger-joints (full joints), for example finger-jointed frame corners. These joints are particularly stable and resilient.

Cross-section weakening

with finger jointing

However, finger-jointing also results in a weakening of the cross-section. In glulam components, however, the weakening caused by the finger-jointing of the individual boards may be neglected.

Further

topics

DERIX

Find your contact person

DERIX

Premium

Exklusive services, newsletter & Co.

Register now and get exclusive access to extensive specialist content. Use our helpful digital service tools such as our X-LAM Designer and stay well informed with our newsletter.