Airship hangar

in Mülheim

Airship hangar

at a glance

Half-timbered arches

in the airship hangar

The gates are spectacular custom-made products. Each gate wing has an area of 400 m² and a dead weight of 72 tonnes. These are moved by four electric motors with 80 hp engine power.

| Building project | Airship hangar Mülheim |

|---|---|

| Construction | Truss arches made of glulam |

| Construction time | 2022 |

| Gross floor area | 3,400 m2 |

| Volume of the wooden components | 1,560 m³ |

| Stored CO2 in the construction | 1,184 tCO2 |

| Avoided CO2 in the construction | 1,420.85 tCO2 |

| Regrowth speed in german forests | 47 minutes |

| Building owner | Westdeutsche Luftwerbung – Theodor Wüllenkemper GmbH Co & KG, Mülheim an der Ruhr, www.wdl-gruppe.de |

| Project management | IB Römling, Essen, www.ibroemling.de |

| Architecture (implementation planning and construction management) | Gronau plan GbR, Wegberg, www.gronau-bau.de |

| Architecture (design and approval planning) | Symk Fischer Architekten GbR, Mülheim an der Ruhr, www.s-f-architekten.de |

| Structural engineering | Ripkens Wiesenkämper Beratende Ingenieure, www.rw-ingenieure.de |

| Werkplanung, Abbund und Montage | DERIX-Group |

Prizes & Awards

for the Airship hangar

German Engineering Award

2024 – State Prize

The airship hangar wins the German Engineering Award 2024 because all the criteria of the competition – design, construction, innovation, resource efficiency and sustainability – have been implemented in this project in an exemplary manner. The airship hangar ideally combines the art of engineering with sustainability criteria.

Timber Construction AwardNRW 2024

Ernst & Sohn Ingenieurbaupreis 2024

The Airship hangar Mülheim was honoured with the Ernst & Sohn Ingenieurbaupreis 2024. The jury recognised the holistic approach to design and execution to create a particularly sustainable structure.

DGNB Gold Certificate

The airship hangar in Mülheim has been awarded the Gold Certificate by the German Sustainable Building Council (DGNB) – a strong sign of future-oriented and sustainable construction.

The award confirms the high quality of the circular and sustainable construction in all relevant criteria: ecology, economy, social aspects, technology, process and location.

Circular

from start to finish

Downloads

for reference

Mikado: A good choice in all aspects

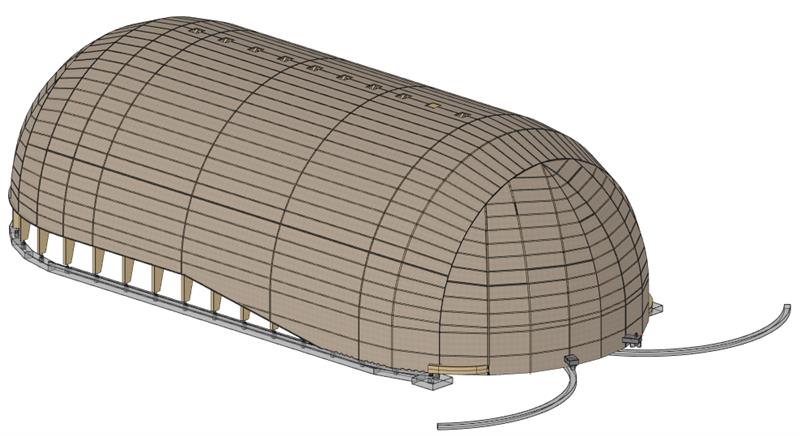

Model views

The model view of the airship hangar shows a complete representation of the structural details of the building.

It illustrates the architectural and structural elements in their entirety and makes the structure of the building comprehensible.