Houtlab

in Nieuwkujik

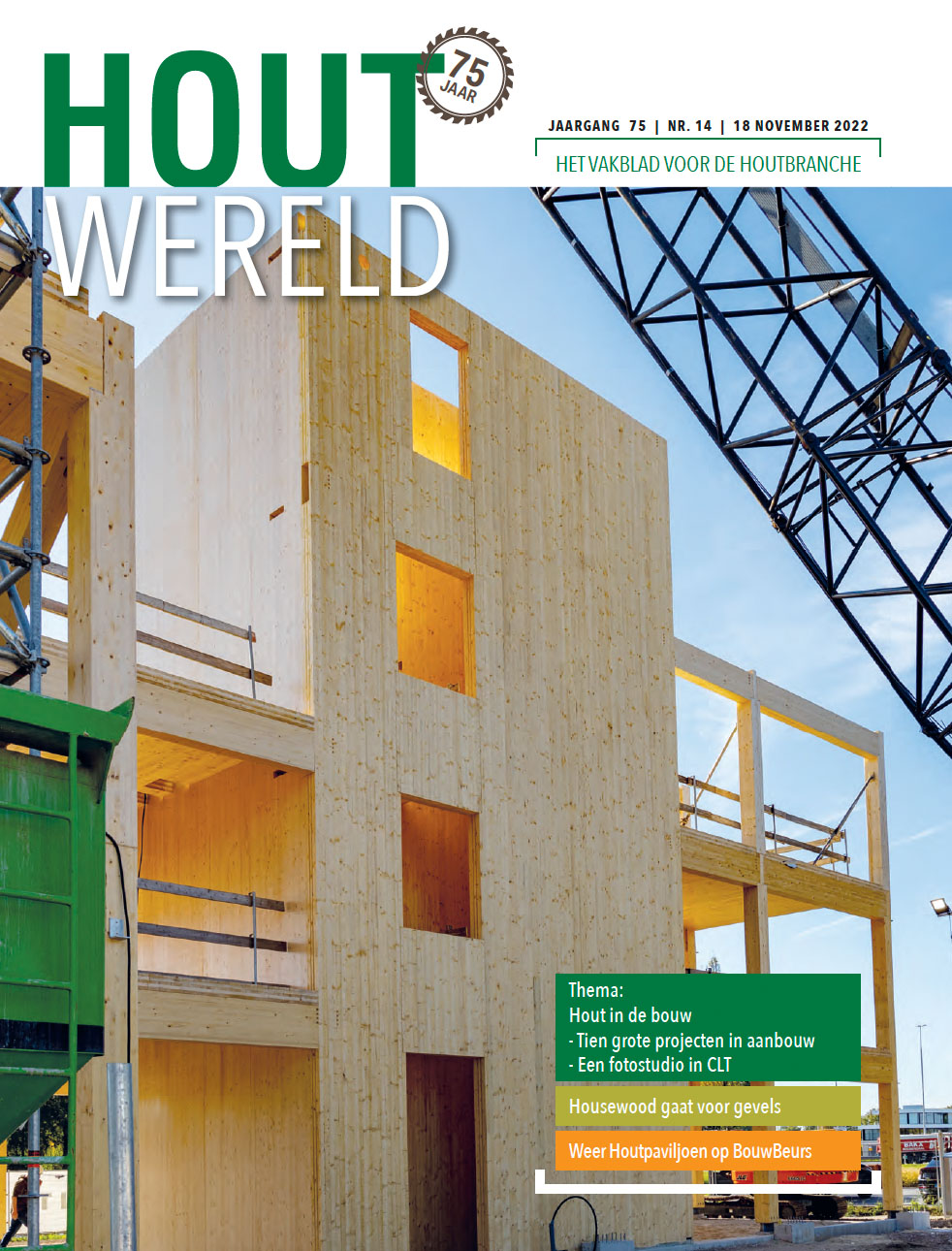

Houtlab in the North-Brabant town of Nieuwkuijk, located on the A59 motorway, is a business hall and office building in one. The building is home to several companies specialising in sustainability, the circular economy and timber construction, including Woody Builders (formerly Woody Building Concepts), who also developed and built the building. Circular and bio-based materials were deliberately used in the construction of the Houtlab. Concrete and steel were only used when it was not otherwise possible. Otherwise, as much wood as possible was used. Houtlab shows what is possible with wood and inspires circular and bio-based construction. It is the first commercial building to fulfil the Paris Proof 2023 standard and also the first building ever to be awarded a Construction Stored Carbon certificate.

Houtlab

at a glance

Houtlab is built almost entirely from bio-based and circular materials, especially wood. The main supporting structure consists of timber columns and beams. A unique feature is that the columns with the crane runway in the hall are also made of wood. The crane runway is acoustically decoupled from the supporting structure. In addition, the industrial hall and the office are connected to each other without vibrations. The floor on the ground floor and the floating screeds are made of round concrete. The other floors are made of X-LAM, as are the roofs, walls, the lift core, the stairs and the stairwells. The exterior façade consists of timber frame elements clad with Frakél slats. This wooden façade runs around the entire building and connects the industrial hall and the office to form a whole. In addition to wood, other bio-based and circular materials were also used. The insulation material in the floors and the façade is bio-based. Circular concrete and steel were used, circular sandwich panels were installed in the industrial halls and circular bitumen is used on the roof of the building. The sound-absorbing elements in the ceilings are made from old work clothes. Even the furniture in Houtlab is circular, from converted fitness equipment to Eames chairs.

| Building project | Houtlab, Hoogpoort, NL – 5253 RN Nieuwkuijk |

|---|---|

| Construction | HTimber structure consisting of columns and beams with X-LAM walls, floors, ceilings, stairs and staircases. |

| Construction time / Completion | July 2022 – April 2023 |

| Usable area | 2216 m³ |

| Volume of the wooden components | 541,3 m³ |

| Stored CO2 in the construction | 410,92 tons CO2 |

| Avoided CO2 in the construction | 493,11 tons CO2 |

| Speed of regrowth in German forests | 16 minutes |

| Building owner | Woody Builders Hoogpoort 3 (Houtlab) 5253 RN Nieuwkuijk Postbus 67 5250 AB Vlijmen www.woodybuilders.nl |

| Architect | SPEE architecten

Vennelaan 4 5062 SR Oisterwijk Nederland www.speearchitecten.nl |

| Engineering office | Adviesbureau Lüning Arnhemsestraatweg 358 Postbus 304 6800 AH Arnhem www.luning.nl |

customer

Testimonials

The advantages of wood

in Houtlab

Houtlab is intended to be a showroom for commercial timber construction and an momentum generator for circular, sustainable and bio-based construction. This is also reflected in the building materials used, including wood. Wood is a natural building material with circular potential. The construction method with prefabricated wooden parts and dry connections not only enabled a quick and clean construction, but also easy dismantling of the building in the future, after which the parts can be reused for other applications. In addition, wood is a lightweight building material, so no piles had to be used at Houtlab. The wood also ensures a healthy indoor climate and a pleasant working environment, which increases the well-being and productivity of employees and reduces absenteeism due to illness.

Sustainable, durable

and energy-neutral

Houtlab is a showroom and knowledge centre for sustainability. Numerous sustainable measures have been taken, such as insulation, solar panels, heat pumps, a water storage tank and a garden with various types of native plants and insect hotels to promote biodiversity. In addition, many bio-based, recycled and reusable materials were used. This has significantly reduced CO2 emissions now and in the future. The timber construction method contributes to this because wood is a raw material that grows back again and again. In addition, trees absorb CO2 during their lifetime, which is stored for a long time during processing into building material and also remains stored when this material is reused. During the construction of the Houtlab, CO2 emissions were further minimised because wood is a lighter material than conventional building materials, making the use of concrete piles unnecessary. Thanks to all these sustainable materials and measures, Houtlab fulfils the Paris Proof 2023 standard, also in terms of greenhouse gas and energy consumption. It is also the first building to be awarded a Construction Stored Carbon certificate.

Further

Topics

DERIX

Find your contact person

DERIX

Premium

Exklusive services, newsletter & Co.

Register now and get exclusive access to extensive specialist content. Use our helpful digital service tools such as our X-LAM Designer and stay well informed with our newsletter.