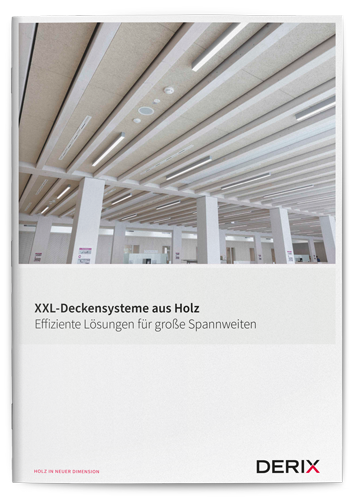

DERIX Ribbed ceiling

Ribbed ceilings are bonded composite cross-sections. They consist of glulam ribs, which are aligned in the main span direction, and upper or lower panelling made of X-LAM. Thanks to the targeted bonding of the two wood-based materials, ribbed ceilings from a span of approx. 6 m represent an effective and economical alternative to pure X-LAM constructions. The existing spaces between the ribs can be used as an installation level. In addition, the physical properties of the ceiling system can be further optimised by inserting additional materials into the spaces between the ribs. Ribbed ceilings are ideal for use in buildings in which large spans are to be realised that have to bear high loads. The main areas of application include industrial and warehouse buildings, office buildings, schools and nurseries. The use of ribbed ceilings can also be advantageous in the area of multi-storey residential buildings and urban redensification.

Advantages of the ribbed ceiling at a glance:

- High performance: high load-bearing capacity with low weight – easy to create stiffening floor slabs

- High efficiency:

– large spans with high loads

– reduced deflection and minimised vibration behaviour thanks to high rigidity - Design flexibility: open and flexible floor plan design thanks to reduction of load-bearing walls

- Reliability: standardised product defined by ETA

- Optimum accuracy of fit: high dimensional accuracy thanks to precise joinery

- Reduction in fasteners: fewer fasteners required due to stiffer bond and optimised component properties

- Attractive appearance: typical timber construction beam view

- Ribbed ceilings offer additional utilisation options:

– Insertion of panel materials for acoustic optimisation

– Installation of technical building equipment - Simplified planning: free pre-dimensioning tool X-LAM Designer as a service

Structure and dimensions

of the ribbed ceiling

In order to produce a DERIX ribbed ceiling in accordance with the technical principles of the ETA, the following dimensions must be observed:

h ≤ 540 mm d 60 – 180 mm

h1 100 – 480 mm

t ≤120 mm

b ≤ 3000 mm

L ≤ 10 m

b1 ≤ 600 mm

Ribbed ceilings can also be manufactured as composite components in accordance with DIN 1052-10. This enables a more flexible geometric design and dimensions that exceed the maximum dimensions specified in ETA 23/0761. However, this is associated with increased manufacturing costs due to a more complex bonding process.

Planning aids for ribbed ceilings

With the DERIX X-LAM Designer, we provide you with a free dimensioning programme that you can use at any time to pre-dimension your ribbed or hollow-core slab.

- Intuitive design software for use both in the course of preliminary design and for the creation of structural documents

- Individual configuration options for the arrangement of the plates, the cross-sections and the materiality of the ribs

- Consideration of the deformation components from shear deformation in addition to the deformation components from bending deformation

- Verification in the ultimate limit state and the serviceability limit state including vibrations

- Hot design in progress

Planning & statics

Which ceiling type

for my building project?

We have compiled and evaluated criteria for architects and planners in this comparison table. This will give you a quick insight into which type of ceiling can offer the greatest benefits for your building project.