Board-stacked ceiling & wood-concrete composite

Technical

Data

| Material properties | Strength class GL 24h |

|---|---|

| Element height | 6 cm < H < 30 cm |

| Standard element width | B = 716 mm |

| Element length | L < 17.95 m |

| Joint spacing | a = 2/3/4 cm |

| Slot width | b = 4 mm |

| Slot depth | t = 10 mm |

| Edits | Rebate groove not visible side Lateral tongue and groove design on request Drill holes Milling |

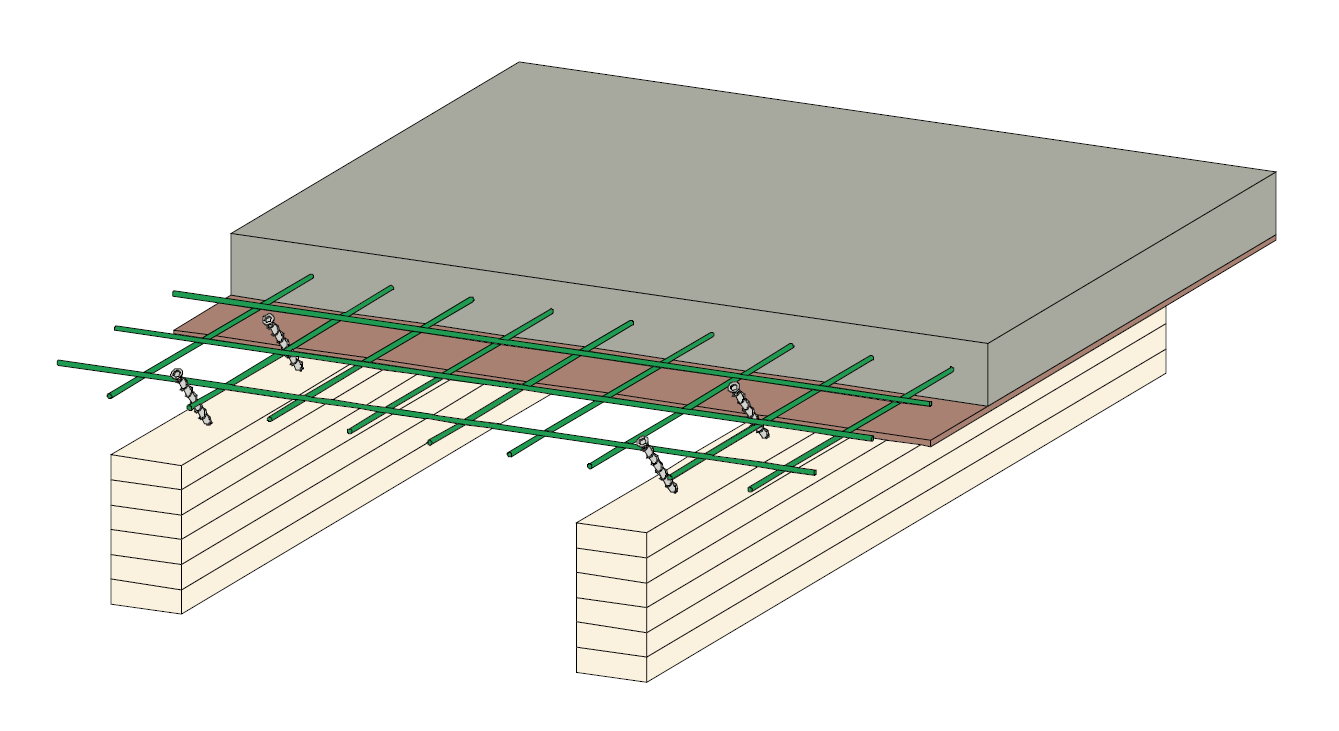

Wood-concrete composite ceiling

HBV floors are a composite building material made of glulam and concrete. The composite effect of the two materials is realised with the help of pin-shaped, glued or form-fit connecting means. In the composite cross-section, the timber cross-section provides the load-bearing function in the tension zone and the concrete provides it in the compression zone. The timber cross-section can be used in the form of a glulam cross-section or as a board stacking element. Due to the composite effect, larger spans can be achieved compared to conventional timber ceiling constructions and the dead weight can be reduced compared to pure concrete constructions. Particularly in areas of increased requirements for serviceability and fire protection, high-performance timber ceiling constructions can thus be realised.

Technical

Data

| Strength of the individual elements | Glulam: GL 24c, concrete C25 / 30, Constructive reinforcement Q188 |

| Dimensions/Length | Maximum element width: 1.00 m; Maximum elemant length: 6.00 m |

| Advantages | High air and impact sound insulation Fire protection possible up to R90 (new standard REI 90) More advantageous Thermal insulation /Good heat storage capacity |

Downloads for

Board-stack ceiling & wood-concrete composite

Pre-dimensioning glulam floor 1 span girder

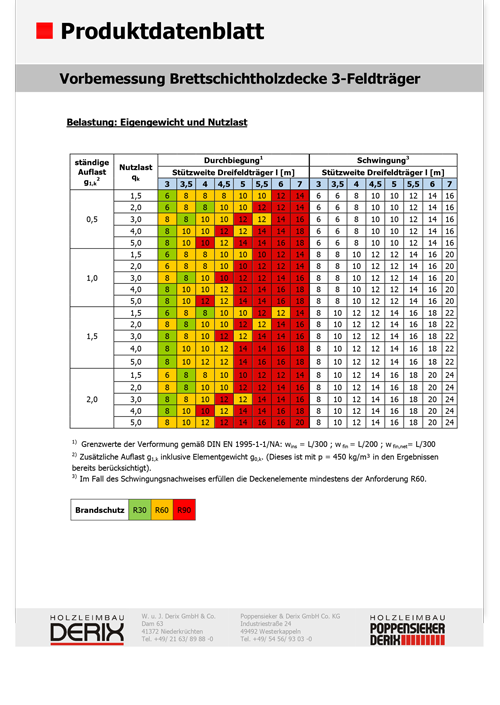

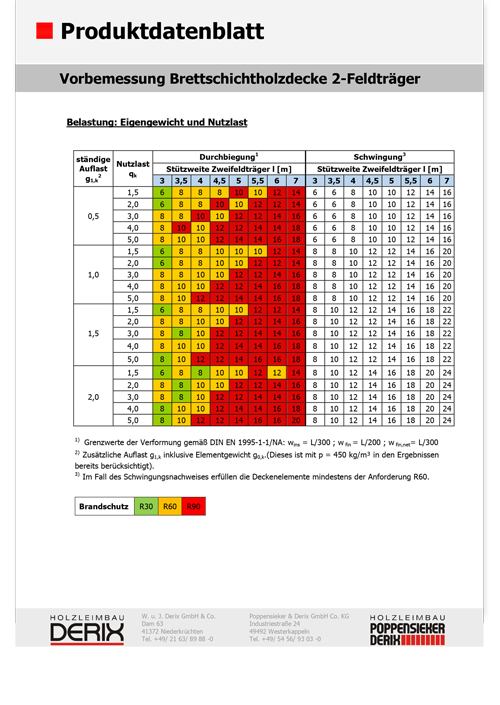

Pre-dimensioning glulam floor 2-field girder