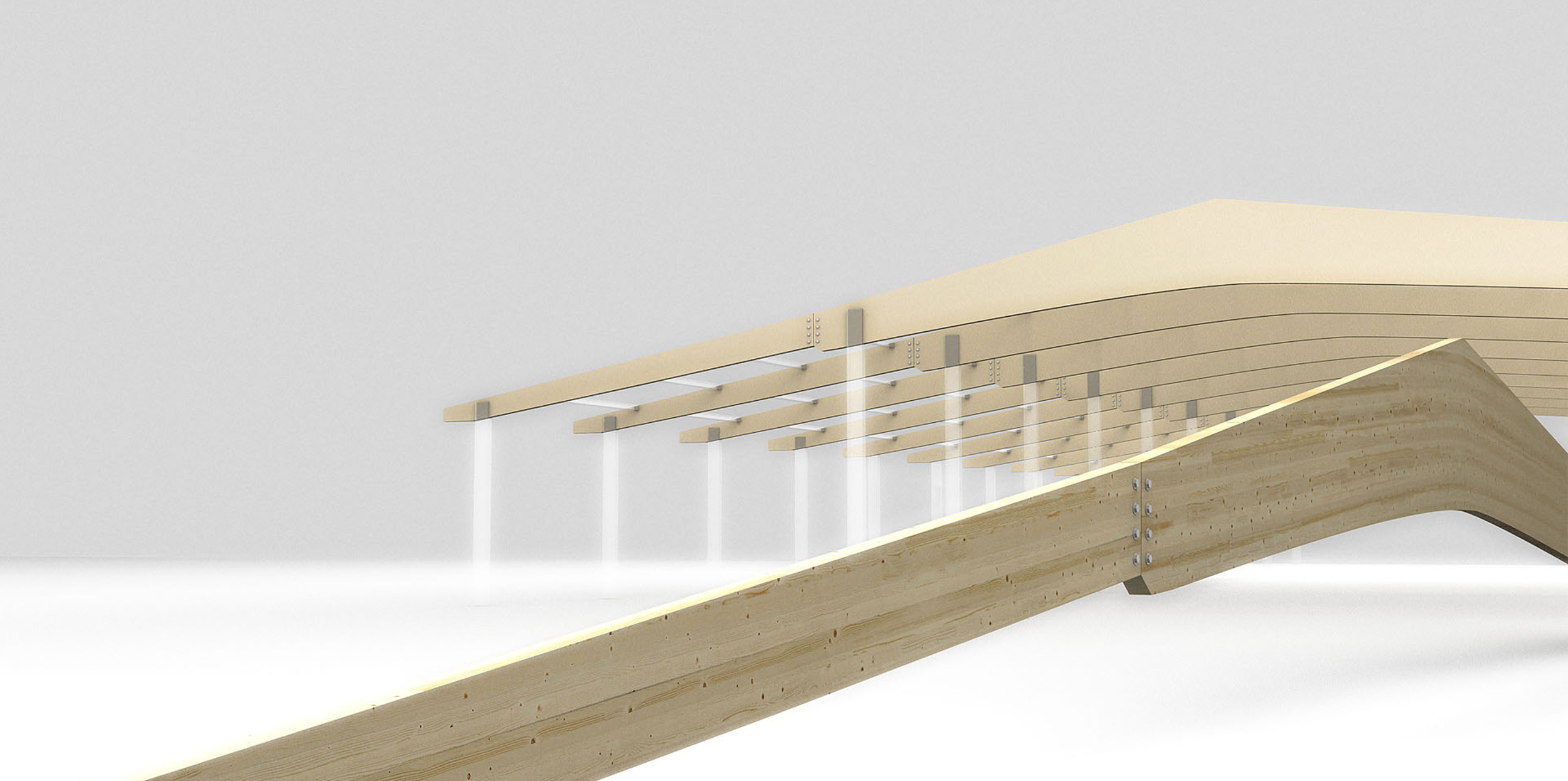

Articulated beams and multi-span beams

Multi-span girders are favoured as purlin systems in the area of hall gables but also for large-scale production halls and warehouses from an economic point of view. Due to the favourable moment distribution, deflections and stress distributions are optimised. To absorb the higher prop moments, coving can be glued on. For larger spans, joints are planned at the moment zero point to optimise the transport of the components. For drainage of the roof area, the hall aisles are slightly inclined in opposite directions (approx. 2 – 5°). The intermediate supports and the external supports can be designed differently depending on the area of application (e.g. reinforced concrete central support clamped, external supports made of timber suspended).

Technical

Data

| Span | 10 – 60 m |

|---|---|

| Roof pitch | – |

| Usual beam spacing (other dimensions possible) | 5 – 10 m |

| Beam width (2 cm preferred dimensions each) | 10 to 26 cm |

| Cantilevers | possible |

| Height of components (for structural design) | h1 = l/16 ; h2 = l/20 to l/25 |

| Possible fire resistance classes | R 30 > without problems R 60 > with additional costs |

| Preferred strength classes | GL 24h/c, GL 28c, GL 30c |

Glulam

Components parts

DERIX

Find your contact person

DERIX

Premium

Exklusive services, newsletter & Co.

Register now and get exclusive access to extensive specialist content. Use our helpful digital service tools such as our X-LAM Designer and stay well informed with our newsletter.