14.07.2025

DERIX biobased:

Production almost entirely with bio-based adhesive

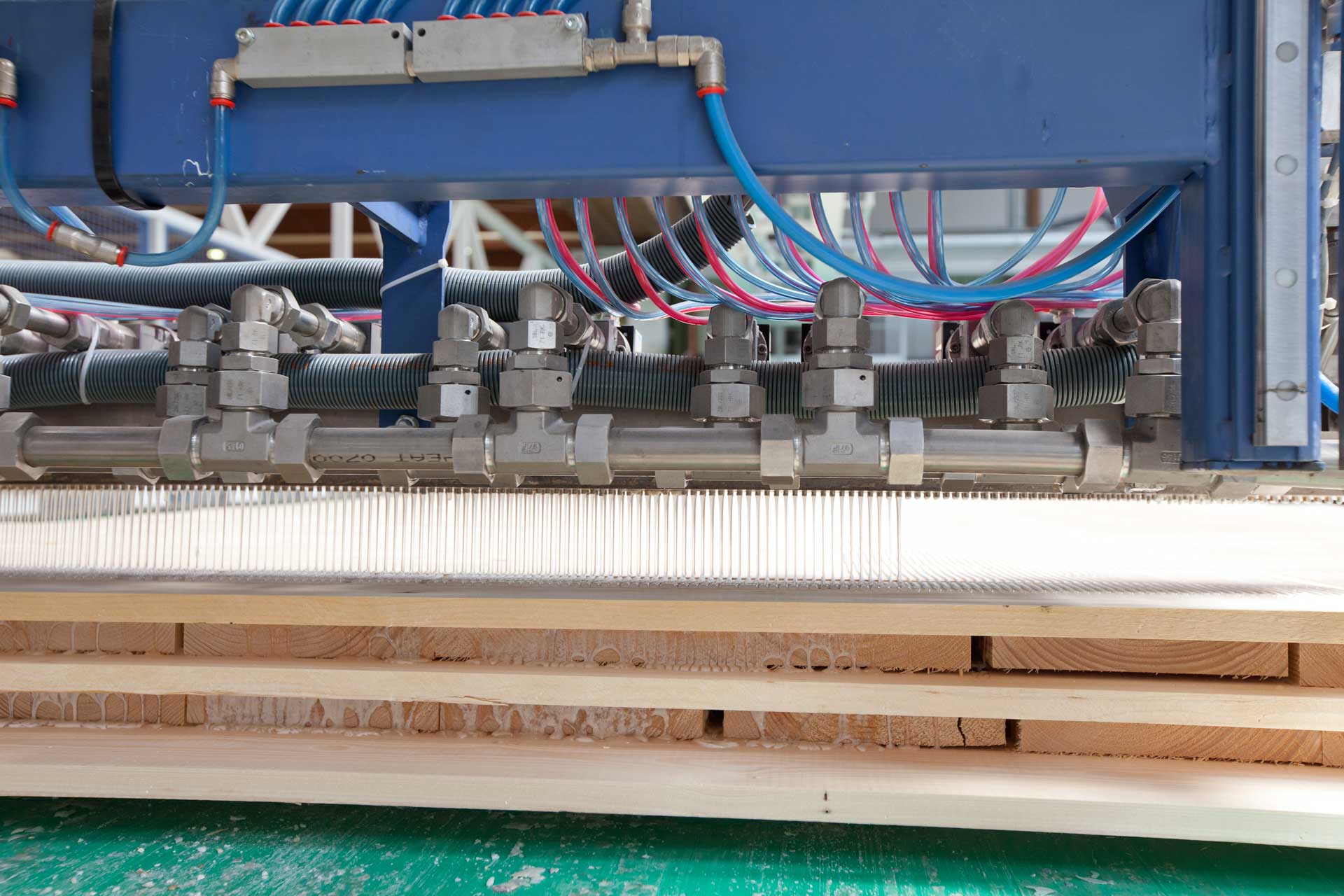

Just one year after the successful launch, the DERIX Group has advanced the use of bio-based adhesives to such an extent that the wooden components are now almost completely glued with the new, bio-based adhesives.

The company relies on the adhesives ‘Henkel Loctite HB S Eco’ and ‘Akzo Grip Pro Plus Nature’, both bio-based variants of the certified and proven predecessors ‘Henkel Loctite HB S’ and ‘Akzo Grip Pro Plus’.

The processing, quality and reliability of the adhesives remain unaffected by the changeover, as the chemical composition of the end product remains unchanged. The significant difference to the predecessor product is that 50-63%* of the chemical starting materials in the new adhesives are no longer obtained from fossil raw materials, but from bio-based sources – i.e. from renewable and partially recycled starting materials. This significantly reduces the CO2 footprint of the adhesive.

‘The DERIX Group is the first timber engineering company in the world to introduce the use of new, bio-based adhesives in its production,’ says Markus Steppler, Managing Director of the DERIX Group. ‘Even though the proportion of adhesive in the ready-to-install solid wood components we deliver is extremely low, we are also consistently driving forward further sustainability optimisations in this area.’

‘After successfully introducing bio-based adhesives for our ’X-LAM” product at our plant in Westerkappeln last year, I am delighted that we are now consistently pursuing this innovative path: By switching to the new ‘Akzo Grip Pro Plus Nature’ glue system for all BSH and X-LAM products from the DERIX Group, we are now relying almost entirely on bio-based adhesives,” explains Markus Brößkamp, Managing Director at the DERIX Group. ‘This not only increases the sustainability of our production processes and our end product, but also makes an active contribution to promoting a circular economy – a goal that we at DERIX are firmly focussed on.’

The DERIX Group prioritises sustainability and circularity. The company has been at the forefront of innovation in this area for years.

It was not until the end of May 2025 that the DERIX Group announced its entry into emissions trading and declared that the CO2 stored in the wooden components it produces would be certified with immediate effect. In October 2024, the company introduced sustainable transport films and in February 2024 it announced the introduction of bio-based adhesives. Just a few months earlier, the company had announced its award as a ‘climate-neutral company’. In May 2021, the DERIX Group made a general commitment to taking back used components its corporate standard. Numerous reference projects ( The Cradle, Airship hangar, ABN Amro Circl) have already been designed and implemented with a view to later dismantling in line with the circular economy (design for dismantling). Derix has been cooperating with madaster, the leading material register in Germany, since the beginning of 2023, thus supporting the reuse of components in the material cycle

Find out more about the implementation of sustainability and circularity at DERIX.